Coil Heater

Product Details:

- Type Other

- Material Stainless Steel

- Voltage 480 Volt (v)

- Power 4000 to 20000 Watt (w)

- Power Source Electric

- Installation Type Other

- Dimension (L*W*H) 60 to 320 Inch (in)

- Click to View more

Coil Heater Price And Quantity

- 750.00 - 5000.00 INR/Piece

- 10 Piece

Coil Heater Product Specifications

- 480 Volt (v)

- Other

- Stainless Steel

- Gaurantee of Workmanship

- Electric

- 60 to 320 Inch (in)

- Other

- 4000 to 20000 Watt (w)

Coil Heater Trade Information

- Mumbai

- Telegraphic Transfer (T/T)

- 1000 Piece Per Month

- 8 Week

- Yes

- Contact us for information regarding our sample policy

- Wooden Case

- Asia Australia North America South America Eastern Europe Western Europe Middle East Central America Africa

- All India

- UL, CE

Product Description

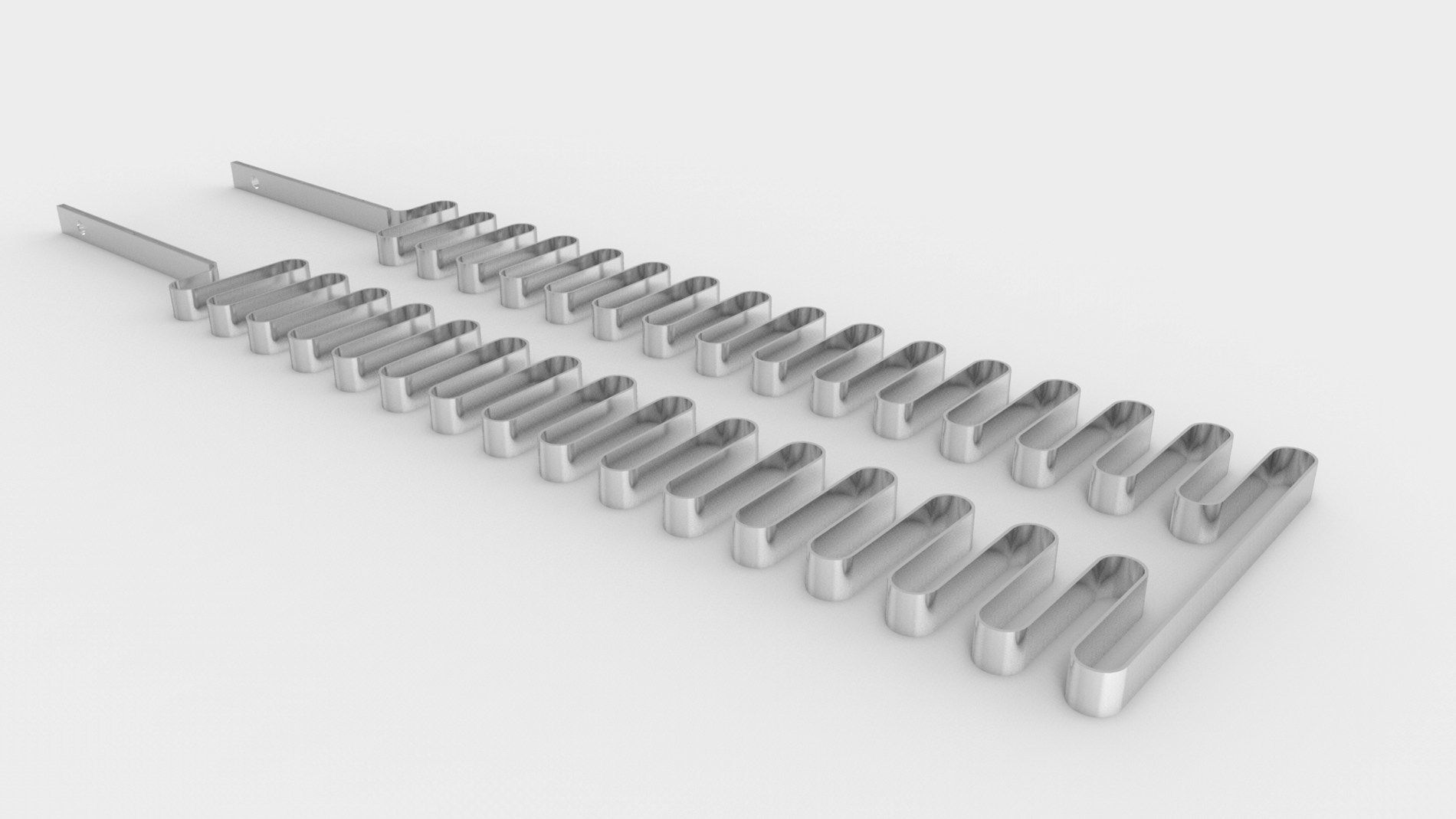

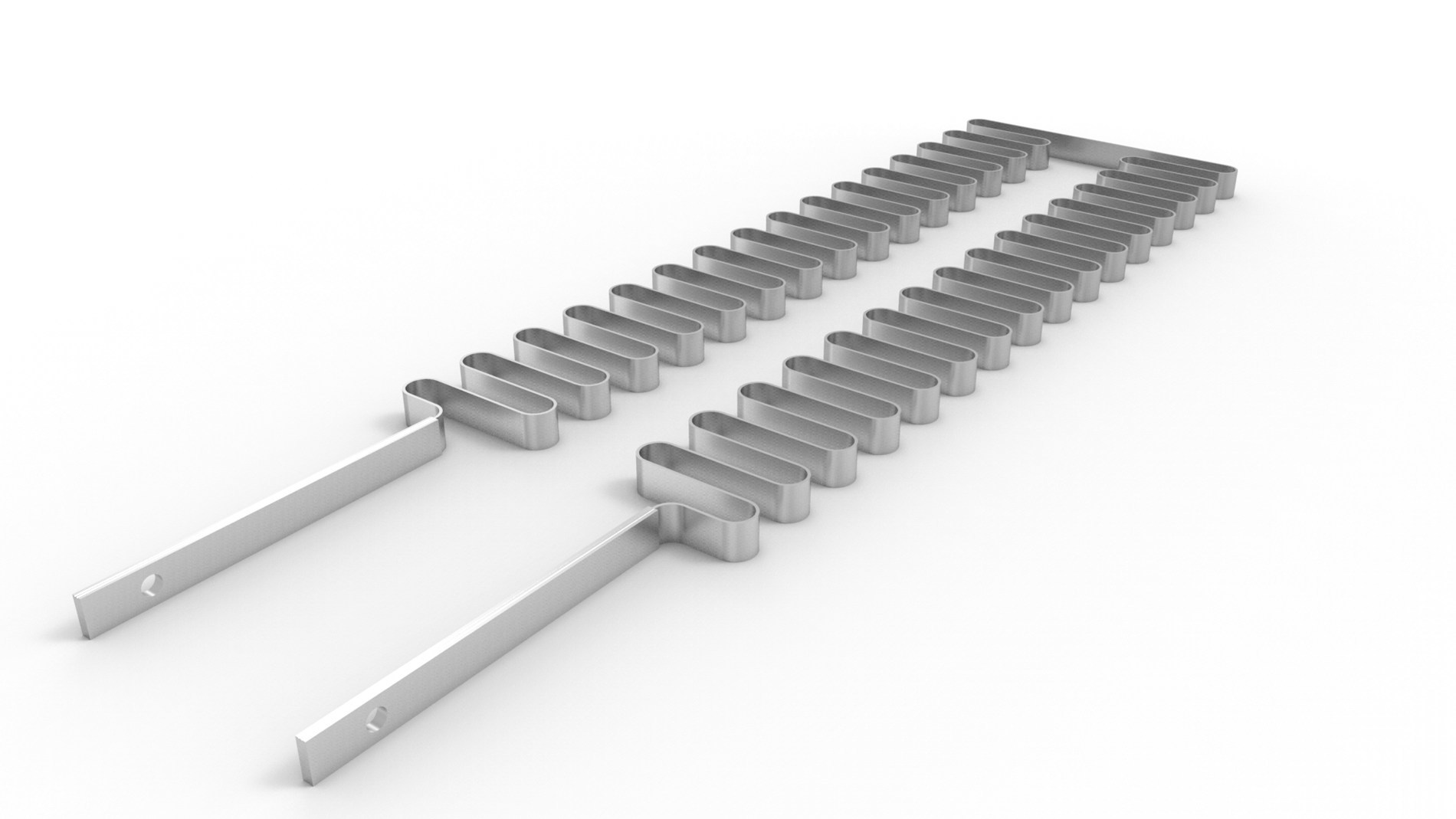

Coil Heater

Open coil heating elements have open circuits consisting of coiled resistance wire (usually Ni- Chrome or FeCrAl) fixed onto a supporting element that heat the medium directly. Termed as the most efficient and versatile while also the most economically feasible solution for heating, these elements have fast heat up times that improve efficiency and have been designed for low maintenance and inexpensive replacement parts. When an electrical current is applied to the wire, it gives off heat. The wire is connected to the control panel which regulates the amount of heat provided by the electric heater and fills the tunnel of the air handling unit. Because of the low mass and fast response time, SSR or SCR switching devices are advisable. They serve as an indirect solution to decrease watt density requirements and prevent heat sensitive materials from breaking down. The heater can be formed into a compact, coiled nozzle heater supplying a full 360 degrees of heat with optional distributed wattage.

The face velocity of the air passing over the open coil elements must not be less than a minimum specified value when the heater is energized. There are three factors that are considered when an appropriate face velocity is calculated, i.e. kW, frame size and heater element type. Sufficient airflow for the required kW in a given frame prevents an overheating condition. Heat must be dissipated away from the heating elements.

Other Products in 'Heater Coils' category

GST : 08AAACT5482C1ZF

|

|

TEMPSENS INSTRUMENTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |